Description

Coil Stud Spec Sheet– PDF

Fast, Low-Cost Method of Attaching Formwork to Steel Structures

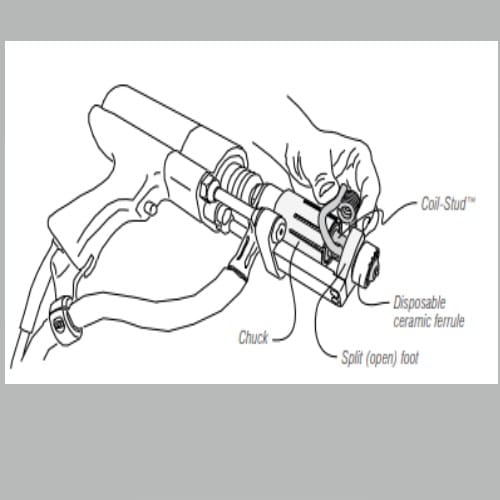

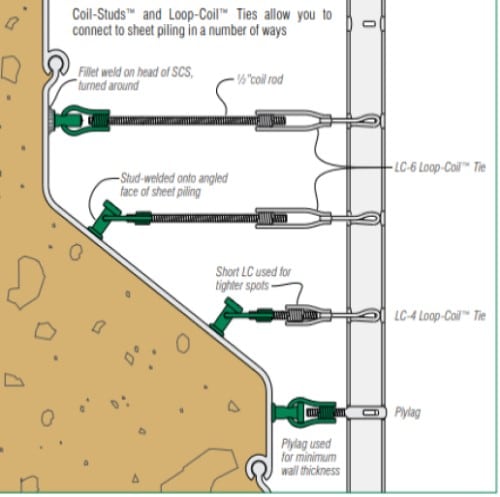

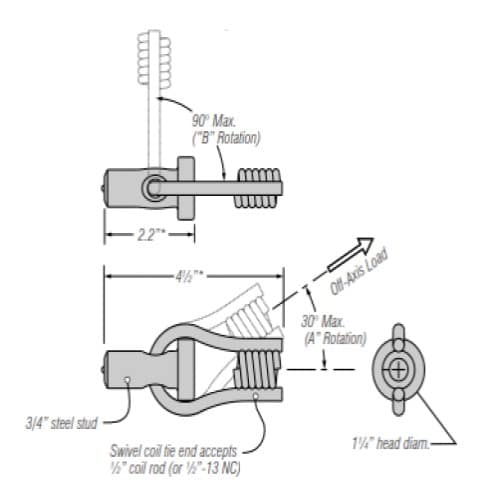

Steel Dog® Coil-Studs™ provide low-cost attachment points for coil hardware based form ties onto steel structures. Typical application: one-sided forming against soldier piles or sheet piling. FEATURES: •Standard 3/4” arc weld stud. •Swivel loop coil tie end to accommodate misalignment between stud placement and formwork tie location. •Accepts standard ½”coil rod or ½”-13 NC rod (SCS-4NC) •Welds in seconds with standard stud welding equipment. •Eliminates expensive external bracing or welding. MATERIAL: Stud is ASTM A108, C1010-1020. Swivel loop wire is AISI C1035. FINISH: None. MAXIMUM SAFE WORKING LOAD: 4500 Lbs. (2-to-1 safety factor). Actual Safe Working Load will depend on quality of weld to substrate. INSTALLATION: •Coil-Studs™ may be welded with standard stud welding equipment designed for drawn arc stud welding, in which an arc is struck between stud and base metal and the stud plunged into the molten steel produced by the arc, creating the weld. The molten steel is contained by a disposable ceramic ferrule (included). A proper weld will be as strong as the stud itself. •Alternatively, the stud can be flipped around and the head of the stud welded conventionally to the base metal, by either stick or MIG welding equipment. •Connection to formwork is made with ½”coil rod directly, or with coil rod and Transition Ties™ (see opposite side). STUD WELDING: •Welder A stud welder capable of at least 1500 amps output is necessary. •Gun The Coil-Stud is compatible with most arc stud welders capable of welding 3/4” shear connector studs. The Coil-Stud™ is shorter than most shear connector studs, however, so an open-style ferrule foot, thin enough not to interfere with the coil loop must be used (see gun drawing).Ensure that coil loop does not contact ferrule foot at end of plunge stroke. •Ferrule The supplied ceramic ferrule is designed for welding to flat, vertical surfaces. Ferrules available for horizontal surfaces or for corners

Reviews

There are no reviews yet.